Extended Reality (XR) is revolutionising various industries by blending physical and digital experiences. While it initially gained traction in the entertainment sector, XR is now essential for promoting sustainability and enhancing supply chains.

By reducing waste, travel emissions, and streamlining processes, XR enables companies to achieve their sustainability objectives. It boosts efficiency, resilience, and transparency by providing real-time insights and predictive analytics.

What XR involves and how it works

Extended Reality (XR) refers to immersive technologies that merge the physical and virtual realms. It includes three main components: Virtual Reality (VR), Augmented Reality (AR), and Mixed Reality (MR), each providing distinct features and uses. These technologies are transforming how we engage with information, environments, and processes.

Key Features of XR

1. Immersive Experiences: XR technologies captivate users by allowing them to actively participate in virtual or augmented environments.

2. Interactivity: XR adapts to user inputs, facilitating dynamic interactions with digital spaces or overlays.

3. Real-Time Data Integration: XR effortlessly incorporates live data, positioning it as a valuable tool for monitoring and informed decision-making.

XR’s Role in Revolutionizing Sustainability

By combining digital simulations with real-world applications, XR allows organisations to minimise waste, save resources, and implement more sustainable operations.

1. Eco-Friendly Design: Virtual prototyping helps cut down on material waste and energy consumption. Ex: 3D modelling tools (e.g., AutoCAD)

2. Virtual Collaboration: XR reduces travel-related emissions by facilitating immersive remote training and collaboration. Ex: Boeing uses XR for remote collaboration to design aircraft components

3. Environmental Monitoring: AR overlays provide real-time tracking of energy use and carbon emissions, supporting swift decision-making.

Ex: Siemens Building Management Systems integrate AR to visualise energy consumption

4. Energy Optimization: Simulations and real-time tools assist in optimising energy consumption in buildings and factories. Ex: In the U.S., facilities using smart energy management systems have achieved annual savings of up to 29% in energy consumption by monitoring and optimizing HVAC, lighting, and other operations in real-time.

5. Consumer Engagement: AR applications highlight sustainability initiatives, product life cycles and eco-friendly practices.

Ex: IKEA’s IKEA Place app uses AR to allow consumers to visualize products in their spaces, promoting eco-friendly options.

6. Improved Recycling: XR improves recycling and resource recovery through effective training and real-time guidance.

How XR is Modernizing Supply Chains

Supply chains play a crucial role in global commerce, and frequently encounter issues such as inefficiencies, limited transparency, and resource waste. XR technologies are changing the game for supply chains by optimising processes, enhancing visibility, and facilitating more informed decision-making.

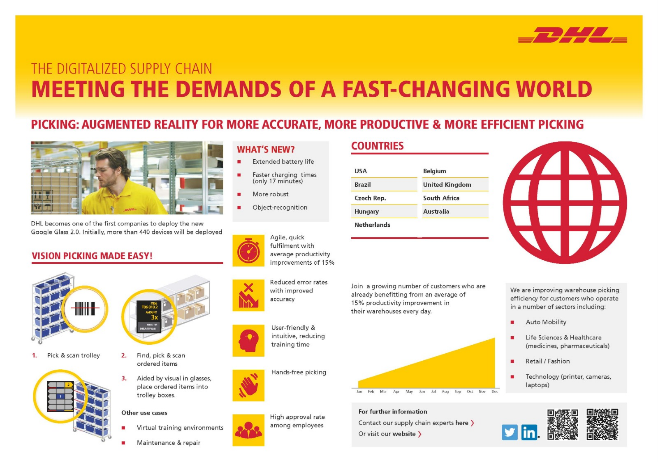

Enhancing Operational Efficiency

AR in Warehousing: Smart glasses equipped with AR assist warehouse workers by overlaying information like item locations, inventory levels, or picking routes. This reduces errors, shortens retrieval times, and boosts productivity.

Example: DHL uses AR-guided picking systems to improve efficiency in warehouses.

Enabling Predictive Maintenance

Supply chains rely heavily on machinery and equipment, where downtime can disrupt operations and escalate costs. XR technologies, particularly AR and MR, support predictive maintenance by overlaying diagnostic data and instructions.

MR for Real-Time Diagnostics – Technicians can use Mixed Reality (MR) headsets to visualise machine data, identify issues, and receive step-by-step repair guidance.

Optimising Logistics and Route Planning

Efficient transportation is vital for sustainable supply chains. XR plays a key role in planning and optimising logistics, ensuring goods are delivered quickly and with minimal environmental impact.

VR Simulations – Businesses can test and plan low-carbon delivery routes or analyse potential delays using virtual models.

Enhancing Supply Chain Transparency

Modern consumers and businesses demand greater transparency in how products are sourced, produced, and delivered. XR technologies offer innovative ways to provide this visibility.

AR Consumer Tools – Brands use AR to allow customers to scan products and see their origins, sustainability certifications, and carbon footprints.

VR for Stakeholder Engagement – Virtual tours of supply chains help investors and partners understand sustainability practices.

Real-Time Decision Support

Supply chain managers often need to make quick, data-driven decisions. XR integrates real-time data visualisations into physical or virtual environments, empowering leaders to respond effectively to disruptions.

AR Dashboards: Display live metrics like inventory levels, delivery statuses, or production bottlenecks, enabling swift action.

Reducing Waste and Resource Usage

XR helps supply chains minimise waste by ensuring better resource utilisation and reducing errors in operations.

AR-Driven Quality Control: AR tools inspect products for defects during manufacturing, reducing waste and ensuring high-quality outcomes.

VR Training: Virtual training environments improve worker efficiency and accuracy, leading to fewer operational mistakes.

Extended Reality (XR) revolutionises sustainability and supply chains through virtual prototyping, AR-guided operations, and real-time insights, enhancing efficiency, transparency, and innovation for a sustainable future.